How to Select Pre-terminated Fibre Optic Cable

22/11/2022 Neil Levett 2045

Why Do I Need Pre-term Fibre Cable?

Pre-term (pre-terminated) fibre cable provides a quick and easy solution for fibre optic installation without requiring any advanced skills or professional termination equipment. Due to the number of different fibre cable and connector types, choosing the correct combinations can be confusing and time consuming. Equipment to terminate the cables on site, such as Fusion Splicers, can run into tens of thousands of pounds.

By selecting a pre-term fibre cable, you can be confident that the cable and connectors are compatible, the glass tubes have been joined professionally, it is the correct cable for your requirements, and it has already been tested for losses.

All this means that specialist fibre cabling jobs that used to be expensive and time consuming are now much more accessible to installers without the need for extensive training or expensive equipment.

How Do I Select the Correct Type of Cable for my Requirements?

Connectec offer a handy feature on all of our pre-terminated fibre optic cable product pages that lets you select the cable mode (single or multi), the number of cores, the connector and the cable length.

Below you will find a brief description of the different types of cable and connectors, and their properties to help you choose the correct combination for your job.

Types of Cable Sheaths & Protection

Tight Buffered

Tight buffered fibre cables are coated with a flexible Acrylate waterproof coating. This makes them thin and flexible but less durable and therefore much more suited to indoor installations where cables may need to pass through small holes and pass around tight bends. Tight buffered cables can be installed underwater although additional protection would be necessary to prevent the cable from becoming damaged.

Loose Tube

In a loose tube fibre cable, the inner fibre cores are suspended in a gel. This provides protection from moisture and temperature, prevents freezing and allows the cable to expand and contract with changes in temperature without damaging the inner cores. Loose tube fibre cable is ideally suited for outdoor installation. Despite being moisture resistant, however, loose tube cable is not recommended for installation underwater.

Loose tube fibre cables are tough, thick and relatively rigid cables which makes them less suited to installation indoors where tight buffered cables would be a better choice.

Corrugated Steel Tape (CST)

Corrugated steel tape is not strictly a cable sheath and is rather an additional layer of protection that is applied under a cable sheath to protect the inner cables. CST is most commonly found in fibre optic cables where the fragile glass cores require additional protection such as when used outdoors but where they high cost of steel wire would be excessive for high volume use. The corrugated steel tape is a semi-rigid layer applied directly beneath the sheath that is made of thin corrugated steel which provides good abrasion, impact and crush resistance to the cable. Cables using CST also cost less and are more flexible and considerably lighter than cables that use steel wire for protection.

Steel Wire Armoured (SWA)

Steel wire armour like corrugated steel tape is applied directly beneath the cable sheath to provide mechanical protection to the cable. A layer is formed by tightly wrapping individual steel wires around the inner sheath and finally applying an outer sheath over it. Steel wire provides the highest level of abrasion, crush and impact resistance making it suitable for use where the cable is exposed to heavy levels of direct wear or potential damage. The layer of steel wire, however, makes the cable significantly less flexible and heavier than other cables so it is only used where absolutely necessary.

Types of Cable Modes

Multimode

Multimode fibre cable has a larger core than Single Mode which allows multiple modes (rays of light) to travel down it simultaneously. Although this sounds beneficial it can create some limitations. Each beam of light takes a slightly different path down the glass tube and reaches the end of the fibre at different times which spreads the signal and makes it weaker, which is made worse over a greater distance. As multimode cable is easier to manufacturer, it is cheaper and therefore most cost effective on short runs up to 300m (1,000ft).

Our Multimode cable is available in 4 different grades, OM1, OM2, OM3 and OM4, with each grade offering different bandwidths and distances.

| Data Speed |

OM1 62.5/125µm |

OM2 50/125µm |

OM3 50/125µm |

OM4 50/125µm |

|---|---|---|---|---|

| 100 Mbs |

2 km |

2 km |

2 km |

2 km |

| 1 Gbs |

275 m |

550 m |

800 m |

1100 m |

| 10 Gbs |

33 m |

82 m |

300 m |

550 m |

| 40/100 Gbs |

- | - | 100 m |

125 m |

Single Mode

Single Mode fibre cable has a very narrow core approximately 9 micrometers (a human hair is around 100 micrometers) which concentrates the beam of light and allows it to travel over much greater distances without as much signal spread as Multimode cable. This type of cable is much harder to manufacture which makes it more expensive. Single Mode cable should only be considered for longer runs between 300m (1,000ft) and 40km (131,234ft).

Number of Cores

Unlike Ethernet cable, fibre optic cable only requires 1 pair of cores to successfully send and receive data. The first core will transmit the light pulses to its destination, the 2nd core receives signals back. Each pair of cores acts like 1 Ethernet cable, albeit over a longer distance and with faster speeds. The more cores that are contained in the cable, the more connections are available, so a 4-core fibre cable would be the same as having 2 individual cables (2 pairs) and a 16-core cable would be the equivalent of 8 cables (8 pairs).

Our fibre cables are available in 4, 8, 12, 16 and 24 core options, in both Multimode and Single mode.

Fibre Connector Choices

Selecting the right connector is often governed by compatibility with the equipment that is being connected. For new installations the compact LC connector is a good choice thanks to its small size and common use on modern networking hardware.

ST Connector

Locking fibre connector found on legacy devices such as switches and data-communications equipment.

SC Connector

Still widely used in fibre installations although newer hardware typically has switched to the more compact space saving LC alternative.

LC Connector

More compact connectors can be found in high density installations and on modern switches and transceivers. This is the most common type of connector currently in use.

FC Connector

Telecommunications connectors with good mechanical isolation although now mostly replaced by SC and LC connectors.

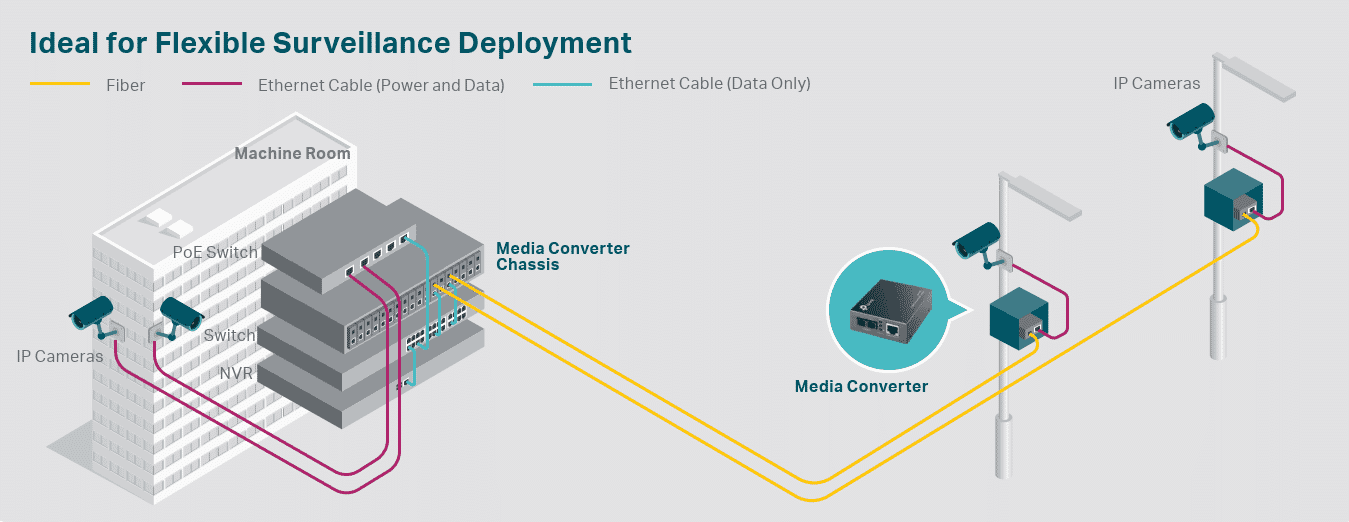

My device doesn't have a fibre port?

Some devices such as switches may not have a socket that will accept these types of connectors. We stock a range of media converters that change the fiber optic connections to RJ45 copper Ethernet networks. These can plug straight into a standard RJ45 ethernet plug on the switch or panel.

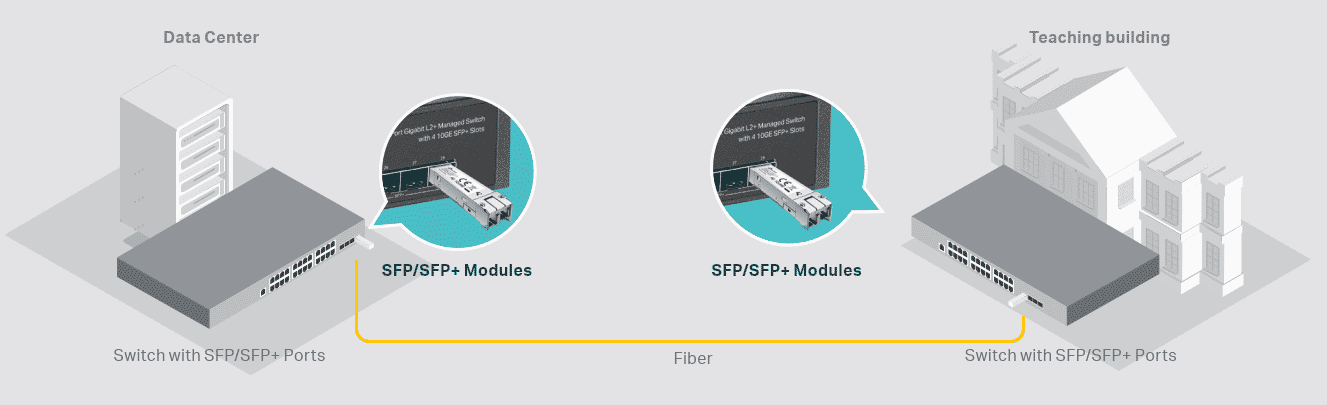

If your device features an SFP port it is possible to use a MiniGBIC SFP Fiber module. These are Hot Pluggable devices that fit into the SFP port and allow for fibre cable to be connected without having to convert to port type to RJ45.

Our full range of fibre media converters and MiniGBIC modules can be found here

For more information or to get a quote, get in touch with one of our fibre specialists.

About Neil Levett

Neil is head of Connetec's marketing team. Neil loves art and music and is always looking for his next adventure.